cnc machining

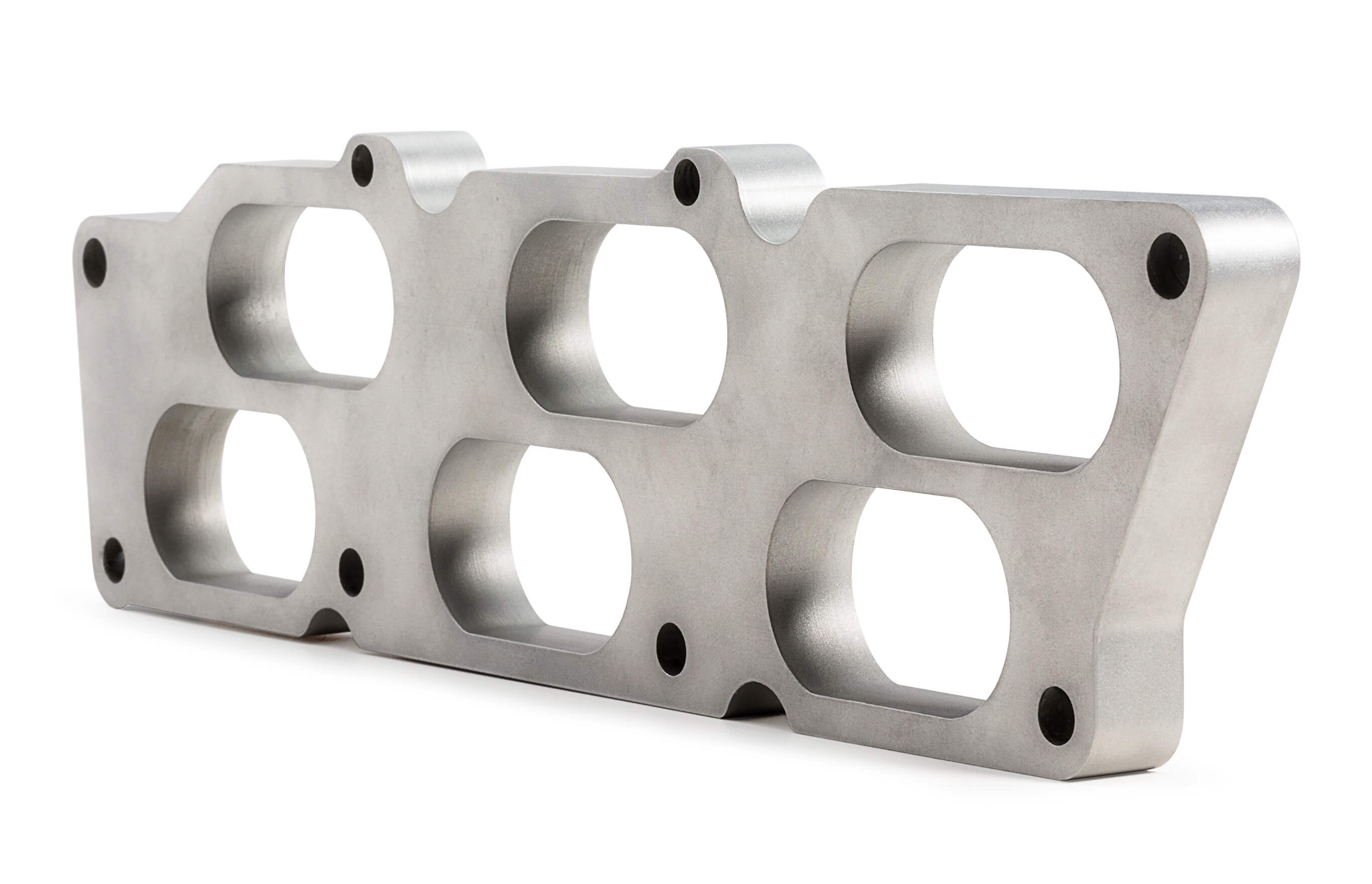

CNC machining is the automated process of removing layers of a material from a stock piece to produce a custom design.

Elite Mold & Engineering has multiple in-house CNC’s that can be used to provide low quantity machined parts. Our facility has 3-Axis and we are capable of machining multiple different materials. We take pride in the quality of our cutters and have various sizes to make sure we can complete highly detailed parts. One of the benefits of working with Elite is our engineering and programming department. Our CNC programmers have the experience and knowledge to ensure the part you receive is exactly what you were looking for.

CNC Materials

BLANK HIDDEN

Aluminum

- Aluminum 5052

- Aluminum 7075

- Aluminum 7075-T6

- Aluminum 6063-T5

- Aluminum 7050-T7451

- Aluminum MIC-6

- Aluminum 6061-T6

- Aluminum 2024-T3

Brass

- Brass C360

- Brass 260

- C932 M07 Bearing Bronze

Copper

- EPT Copper C110

- Copper 101

Plastics

- ABS

- Acetal

- Acrylic

- Nylon 6/6

- PEEK

- Polycarbonate

- PTFE

- Polypropylene

Steel

- Alloy Steel 4130

- Alloy Steel 4140

- ASTM A36

- Stainless Steel 15-5

- Stainless Steel 17-4

- Stainless Steel 18-8

- Stainless Steel 303

- Stainless Steel 304

- Stainless Steel 316/316L

- Stainless Steel 416

- Stainless Steel 420

- Steel 1018

- Steel A36

Zinc

- Zinc Sheet Alloy 500

Advantages of Elite

COST SAVINGS – By utilizing soft-tooling we save timing on machining and pass those savings on to our customers.

KNOWLEDGE – We have been around since 1982, and our staff has the experience provide valuable input.

SPEED – We cut weeks off normal lead times, by specializing in quick turnaround projects and smaller quantities.

QUALITY – We are ISO9001:2015 certified, and have all the necessary equipment and personnel to ensure quality parts and accurate reporting.