CommunicationShipping & Tariff CostConfidentiality & ITARQualification All in One Place

Four Advantages Of Utilizing A Domestic Tooling Source:

Elite Mold & Engineering – Domestic Tooling Experts

Recent Posts

Addressing the Common Design Issues in Injection Molding Plastics

At Elite Mold & Engineering, we try to ensure the success of every injection molding project by addressing any design issues well before production is underway. Our integrated prototyping and product development services bring any potential issues to light, while...

Rapid Injection Molding: An Increasingly Crucial Service for Supply Chain Sustainability

Rapid injection molding is one of the key ways that American manufacturers have risen to the challenges of today’s global supply chain. It’s no secret that most plastic products are made in China. Traditionally, when customers thought of molded plastics, Chinese...

A Guide to STL Files for 3D Printing Projects: STL vs. CAD Models and Other Critical Info

Creating a custom STL file for your parts is one of the crucial early steps in the 3D printing process. Essentially, an STL file is a 3D model that precisely describes the surface geometry of your part as a complex structure built up from interlinked triangles. We’ll...

Rapid Prototyping Techniques Compared: Injection Molding, 3D Printing, and CNC Machined Prototypes

Elite Mold & Engineering specializes in three of the most flexible high-speed prototyping services on the market: rapid injection molding (RIM), 3D printing, and low-volume CNC machining solutions. Each of the three processes comes with its own set of unique...

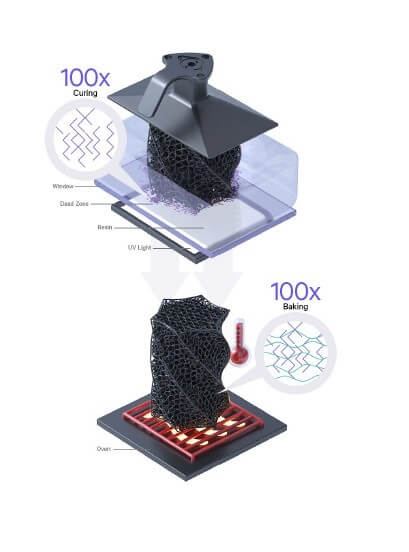

When it comes to manufacturing custom 3D printed parts quickly, accurately and consistently, carbon Digital Light Synthesis (DLS) technology offers a number of advantages when compared to other common 3D printing methods, such as Digital Light Processing (DLP) and Selective Laser Sintering (SLS).

Also referred to as Continuous Liquid Interface Production (CLIP), DLS 3D printers can streamline the manufacturing of high-quality, fully dense parts with tight tolerances and outstanding surface finishes.

Production-Quality Printed Parts with Full Density

Carbon DLS printing can reliably manufacture production-ready parts with a high level of infill density. The ability to print end-use quality parts streamlines all design phases and helps you seamlessly transition your project into full-scale production. DLS printed parts are also perfect for on-demand production applications and just-in-time (JIT) manufacturing projects.

Quick Turnaround and Rapid Production Capabilities

The speed afforded by DLS 3D printing is highly beneficial for both quick-turnaround production and rapid prototyping projects. Whether you are trying to beat your competition to market or streamline the process of design iteration, carbon DLS is an ideal solution.

Greater Material Flexibility

Compatible with a variety of elastomers and a wide range of engineering-grade rigid materials, carbon DLS offers greater versatility in design for your products. Compared to many other 3D printing methods, DLS lets us choose a more optimized material for each custom application – optimized for manufacturing quality and consistency, as well as cost.

Extremely High Quality and Consistency

In terms of quality and consistency, carbon DLS 3D printing is in the top tier of additive manufacturing processes. The technology is able to consistently produce fully dense isotropic parts which are stronger, more reliable, and higher quality in appearance.

A Better Surface Finish for Premium Aesthetics

Speaking of appearance, DLS printed parts offer an outstanding surface finish, giving your products a premium aesthetic. Essentially, the superior structure of DLS printed plastics runs all the way through the structure of the part and shines through at the surface. Gone are the days of cheap-looking brittle parts, with DLS 3D printing offering an appearance comparable to injection molded plastics.

The Greater Michigan Region’s Leading 3D Printed Part Manufacturer

Elite Mold and Engineering is an experienced American contract manufacturer offering state-of-the-art additive manufacturing services via carbon DLS 3D printing technology.

Our company has built a reputation on unparalleled quality, consistency, and customer service in the realm of plastic injection molding since 1982. We are an ISO 9001:2015 and ITAR registered domestic manufacturer specializing in a wide range of industries – from precision aerospace and automotive components to cutting-edge industrial and medical tech.

Communication

Confidentiality & ITAR

No Additional International Shipping or Tariff Cost

Qualification All In One Place

Let Elite Become Your Preffered Domestic Tooling Partner

Discover the multitude of benefits when you choose a domestic tooling source. With our expertise, experience, and commitment to quality, we provide a multitude of key advantages that will streamline your operations. Our local presence ensures seamless communication, offering you the convenience of direct and efficient collaboration. Elite’s stringent quality control measures guarantee precision and reliability, delivering top-notch tooling solutions tailored to your specific needs. Also, by choosing a domestic source, you support local businesses and contribute to the growth of your community. Our quick turnaround times ensure that you stay ahead of the competition, enabling you to meet even the tightest project deadlines. Embrace the numerous advantages of a domestic tooling source and watch your productivity soar.