CommunicationShipping & Tariff CostConfidentiality & ITARQualification All in One Place

Four Advantages Of Utilizing A Domestic Tooling Source:

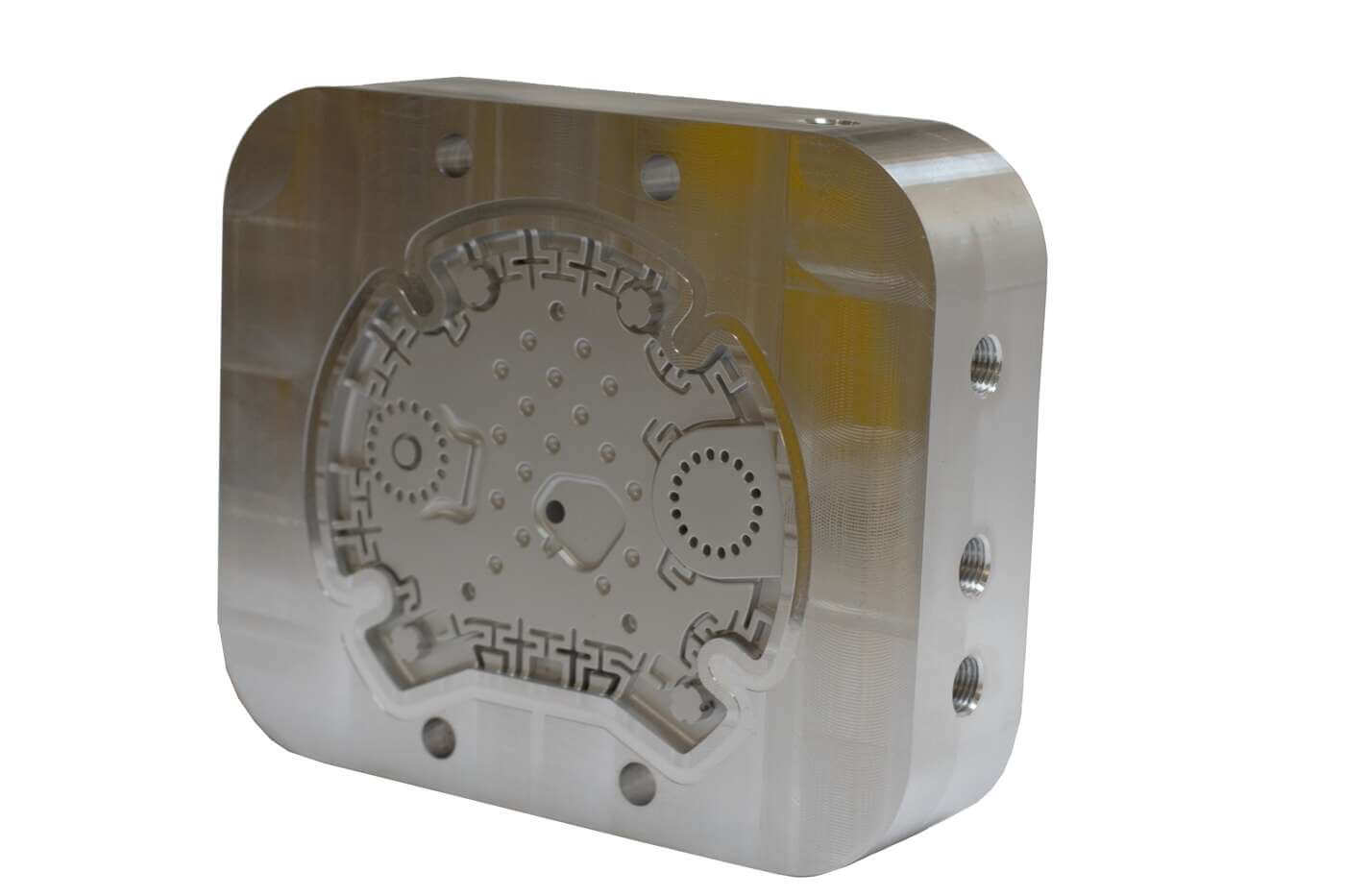

Elite Mold & Engineering – Domestic Tooling Experts

Recent Posts

Addressing the Common Design Issues in Injection Molding Plastics

At Elite Mold & Engineering, we try to ensure the success of every injection molding project by addressing any design issues well before production is underway. Our integrated prototyping and product development services bring any potential issues to light, while...

A Guide to STL Files for 3D Printing Projects: STL vs. CAD Models and Other Critical Info

Creating a custom STL file for your parts is one of the crucial early steps in the 3D printing process. Essentially, an STL file is a 3D model that precisely describes the surface geometry of your part as a complex structure built up from interlinked triangles. We’ll...

Rapid Prototyping Techniques Compared: Injection Molding, 3D Printing, and CNC Machined Prototypes

Elite Mold & Engineering specializes in three of the most flexible high-speed prototyping services on the market: rapid injection molding (RIM), 3D printing, and low-volume CNC machining solutions. Each of the three processes comes with its own set of unique...

A Guide to DLS 3D Printing Technology – How It Works, Materials, and Advantages

Digital light synthesis, or DLS 3D printing is one of the many emerging methods of additive manufacturing. A uniquely advanced VAT polymerisation process, DLS produces full-density plastic parts and prototypes with fine detail and excellent surface finishes. DLS 3D...

Rapid injection molding is one of the key ways that American manufacturers have risen to the challenges of today’s global supply chain.

It’s no secret that most plastic products are made in China. Traditionally, when customers thought of molded plastics, Chinese manufacturing is what would come to mind by default. The “Made in the USA” stamp of approval often seemed all but absent from an increasingly large sector of the manufacturing realm – at least in automotive parts and consumer product spaces.

However, with today’s rapid injection molding technology and the ongoing trend of onshoring, more and more of our plastic products are produced right here at home – Shelby Township, Michigan, in the case of Elite Mold & Engineering.

From the critical plastic devices that some people literally depend on to the everyday gadgets that almost everyone uses, rapid injection molding helps our nation meet its market demand without purchasing from overseas, thus avoiding potential disruptions within the international supply chain.

Rapid Injection Molding (RIM) Supports the American Supply Chain:

A More Steady and Reliable Source for Your Products

You can generally work much more directly, efficiently, and effectively with American manufacturers compared to our overseas counterparts. In part that’s due to proximity, as well as the lack of language barriers. In either case, we provide a more timely and reliable source for your products by carefully setting up the production process and sticking to schedule.

Of course, constant communication and collaboration are key – especially in the early stages of your injection molding project when the process is still being fine-tuned and established. At Elite, we pride ourselves on responsive communication and customer service to make sure you get the exact products you want when you need them.

Avoiding Supply Chain Disruptions and International Shipping Delays

Speaking of ensuring your products are delivered on time, our products ship straight from the heart of Michigan rather than across the ocean. That means you avoid the cost and logistical complexity of international shipping – not to mention the higher potential of shipping delays and canceled orders.

With rapid injection molding for prototypes or low-volume projects, we can cut the turnaround time down even further and have your products delivered in record time.

On-Demand Injection Molding for Just-in-Time Manufacturing

Succeeding in today’s market exceedingly requires lean manufacturing for better efficiency. Many American vendors simply can’t rely upon offshore manufacturers due to the extended turnaround times – not to mention the volume requirements needed to make the project economical, and all the logistics that comes along with higher inventory.

Because our company is lean and local (relatively speaking), we can respond to your changing volume requirements at the drop of a hat. We provide on-demand injection molding services that give you the exact number of products you need when you need them. And because your products don’t have to ship across the ocean, we can typically get them delivered to you ahead of your competitors who turned to offshoring, helping you potentially beat them to market.

Supporting the American Economy and a More Sustainable Future

Not to get too sentimental, but the new manufacturing technologies available to today’s injection molding companies have helped revitalize the industry. That means creating more domestic jobs, supporting American workers, and ultimately helping the US economy grow into the future. And since that future is now focusing more and more on sustainability, choosing American manufacturers who use the most efficient production technologies available is more important than ever.

Michigan’s Premier Plastic Injection Molding Company Since 1982

Elite Mold & Engineering has provided quality-backed injection molding services to the Great Lakes region and beyond since 1982. By embracing new state-of-the-art technologies in plastic injection molding and additive manufacturing, we deliver dependable, economical prototyping and low-volume production solutions to the industrial manufacturing sector and beyond.

Communication

Confidentiality & ITAR

No Additional International Shipping or Tariff Cost

Qualification All In One Place

Let Elite Become Your Preffered Domestic Tooling Partner

Discover the multitude of benefits when you choose a domestic tooling source. With our expertise, experience, and commitment to quality, we provide a multitude of key advantages that will streamline your operations. Our local presence ensures seamless communication, offering you the convenience of direct and efficient collaboration. Elite’s stringent quality control measures guarantee precision and reliability, delivering top-notch tooling solutions tailored to your specific needs. Also, by choosing a domestic source, you support local businesses and contribute to the growth of your community. Our quick turnaround times ensure that you stay ahead of the competition, enabling you to meet even the tightest project deadlines. Embrace the numerous advantages of a domestic tooling source and watch your productivity soar.