CommunicationShipping & Tariff CostConfidentiality & ITARQualification All in One Place

Four Advantages Of Utilizing A Domestic Tooling Source:

Elite Mold & Engineering – Domestic Tooling Experts

Recent Posts

Addressing the Common Design Issues in Injection Molding Plastics

At Elite Mold & Engineering, we try to ensure the success of every injection molding project by addressing any design issues well before production is underway. Our integrated prototyping and product development services bring any potential issues to light, while...

Rapid Injection Molding: An Increasingly Crucial Service for Supply Chain Sustainability

Rapid injection molding is one of the key ways that American manufacturers have risen to the challenges of today’s global supply chain. It’s no secret that most plastic products are made in China. Traditionally, when customers thought of molded plastics, Chinese...

A Guide to STL Files for 3D Printing Projects: STL vs. CAD Models and Other Critical Info

Creating a custom STL file for your parts is one of the crucial early steps in the 3D printing process. Essentially, an STL file is a 3D model that precisely describes the surface geometry of your part as a complex structure built up from interlinked triangles. We’ll...

Rapid Prototyping Techniques Compared: Injection Molding, 3D Printing, and CNC Machined Prototypes

Elite Mold & Engineering specializes in three of the most flexible high-speed prototyping services on the market: rapid injection molding (RIM), 3D printing, and low-volume CNC machining solutions. Each of the three processes comes with its own set of unique...

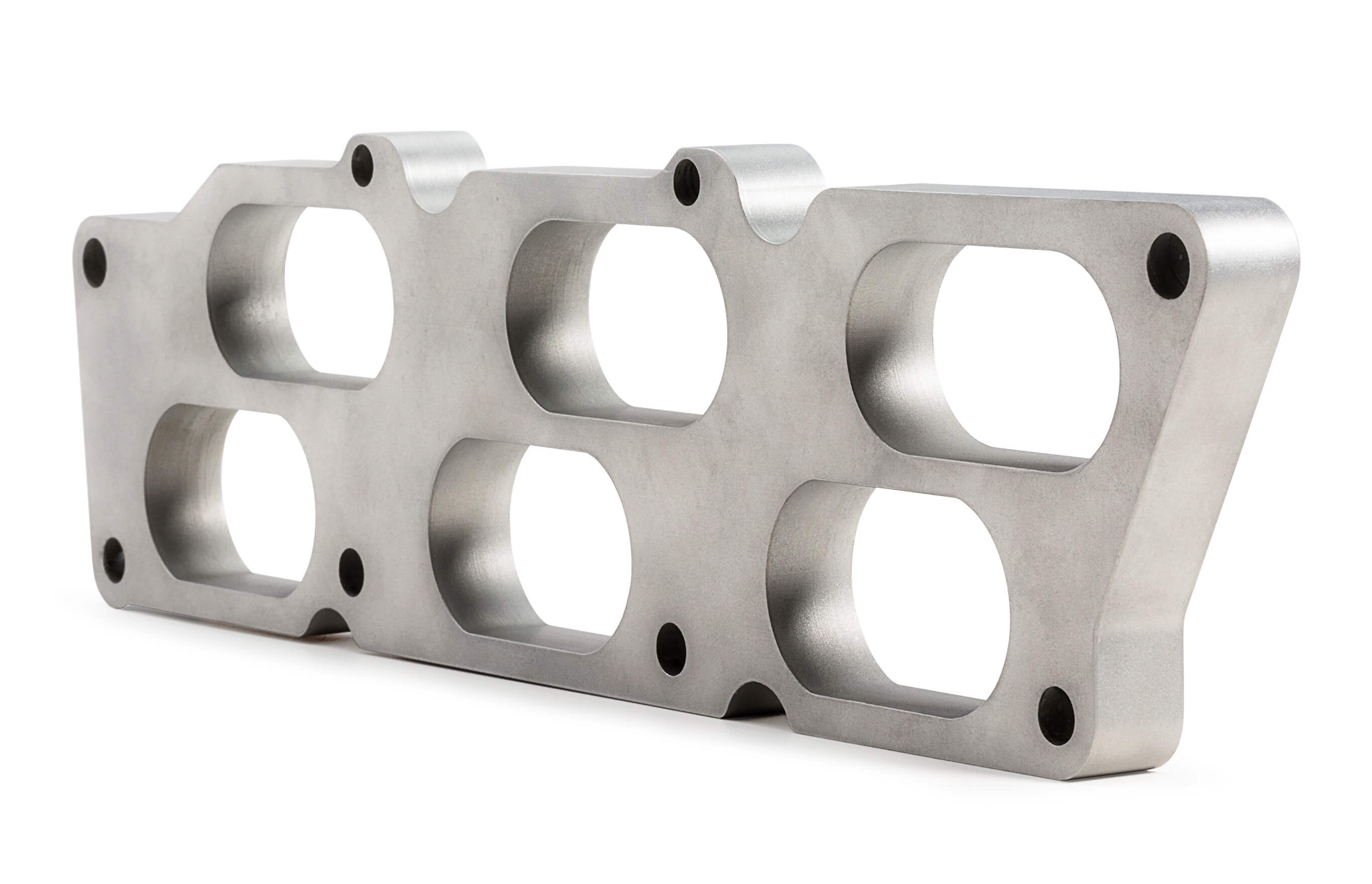

In many ways, multi-axis CNC machining services have become the industry standard for manufacturing highly complex components that require precision tolerances. Compared to manual machining processes, which often require numerous difficult setups along with skilled, intensive manual labor, our 3-axis CNC machines offer much greater flexibility to tackle intricate part designs as quickly and accurately as possible. In fact, we’re often able to automate the entire manufacturing process within a single machine cycle.

While we specialize in plastic injection molding combined with 3D printing solutions, Elite Mold & Engineering also utilizes 3-axis CNC machines to provide low-volume custom machining services. Our in-house CNC machining department rounds out our capabilities as a single-source American manufacturer, helping us to streamline a wider range of projects within our facility right here in Shelby Township, Michigan.

High Precision and High Complexity

To put it simply, 3-axis CNC machining provides three planes of movement for the cutting tool to travel within relative to the workpiece. That means the tooling can be precisely positioned at different angles to produce complex shapes, contours, and intricate machining features – all without having to stop and reposition the workpiece.

Rapid Response and Quick Turnaround

Our ability to produce custom parts in a single machining cycle, combined with the reduced setup steps and workpiece handling, help us minimize our lead times and minimize turnaround for many projects. This is especially true for complex parts that would otherwise require numerous secondary operations – such as drilling, polishing, or deburring.

While other injection molding companies might have to contract out all custom machining projects, or send you off seeking a secondary provider, Elite Mold & Engineering provides streamlined in-house CNC machining services backed by our industry-leading expertise and experience.

A Highly Efficient Rapid Prototyping Solution

The quick turnaround afforded to us through 3-axis CNC machining is also ideal for rapid prototyping projects. Combined with our quick-turnaround 3D printing services for plastic prototypes, our custom machining capabilities give us even more flexibility to rapidly prototype complex metal parts or custom machined plastics.

Quality American CNC Machining Services for Prototype and Low-Volume Projects

Elite Mold and Engineering provides all of the custom manufacturing services required to produce your complex products as quickly and cost-effectively as possible. Our in-house capabilities range from state-of-the-art injection molding and 3D printed plastics to 3-axis CNC machining solutions for high-precision products. An ISO 9001:2015 registered American manufacturer, our company is committed to delivering superior quality and consistency with every project.

Communication

Confidentiality & ITAR

No Additional International Shipping or Tariff Cost

Qualification All In One Place

Let Elite Become Your Preffered Domestic Tooling Partner

Discover the multitude of benefits when you choose a domestic tooling source. With our expertise, experience, and commitment to quality, we provide a multitude of key advantages that will streamline your operations. Our local presence ensures seamless communication, offering you the convenience of direct and efficient collaboration. Elite’s stringent quality control measures guarantee precision and reliability, delivering top-notch tooling solutions tailored to your specific needs. Also, by choosing a domestic source, you support local businesses and contribute to the growth of your community. Our quick turnaround times ensure that you stay ahead of the competition, enabling you to meet even the tightest project deadlines. Embrace the numerous advantages of a domestic tooling source and watch your productivity soar.