CommunicationShipping & Tariff CostConfidentiality & ITARQualification All in One Place

Four Advantages Of Utilizing A Domestic Tooling Source:

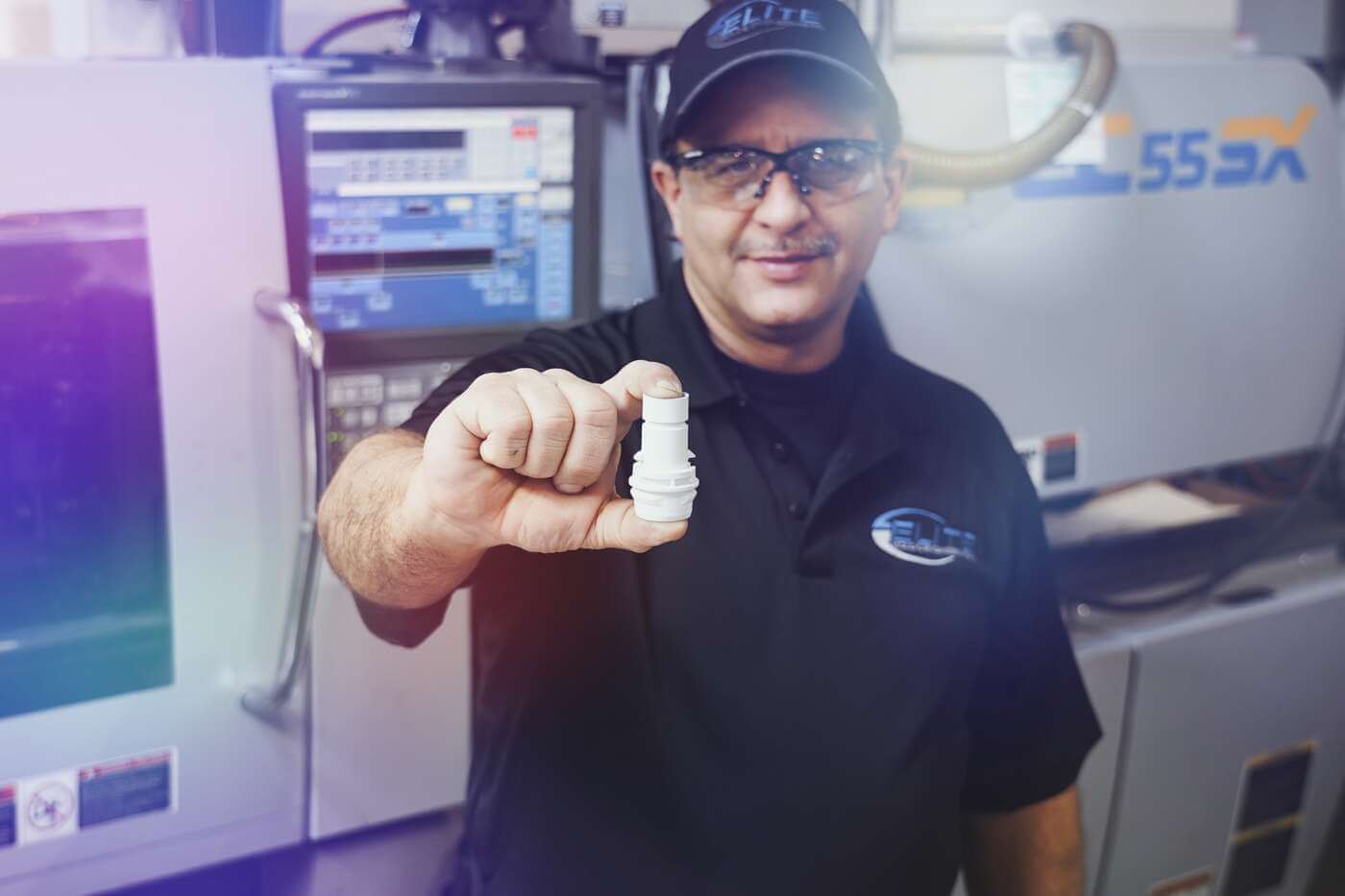

Elite Mold & Engineering – Domestic Tooling Experts

Recent Posts

Addressing the Common Design Issues in Injection Molding Plastics

At Elite Mold & Engineering, we try to ensure the success of every injection molding project by addressing any design issues well before production is underway. Our integrated prototyping and product development services bring any potential issues to light, while...

Rapid Injection Molding: An Increasingly Crucial Service for Supply Chain Sustainability

Rapid injection molding is one of the key ways that American manufacturers have risen to the challenges of today’s global supply chain. It’s no secret that most plastic products are made in China. Traditionally, when customers thought of molded plastics, Chinese...

A Guide to STL Files for 3D Printing Projects: STL vs. CAD Models and Other Critical Info

Creating a custom STL file for your parts is one of the crucial early steps in the 3D printing process. Essentially, an STL file is a 3D model that precisely describes the surface geometry of your part as a complex structure built up from interlinked triangles. We’ll...

Rapid Prototyping Techniques Compared: Injection Molding, 3D Printing, and CNC Machined Prototypes

Elite Mold & Engineering specializes in three of the most flexible high-speed prototyping services on the market: rapid injection molding (RIM), 3D printing, and low-volume CNC machining solutions. Each of the three processes comes with its own set of unique...

To that end, injection molding and 3D printing services are two of the best modern manufacturing processes for custom plastic products, with each one being uniquely optimizable for different product types and/or volume requirements.

Custom Prototype Manufacturing and Product Development

3D printing is generally the most effective manufacturing solution for rapid prototyping projects because it provides the quickest turnaround possible. It’s a highly efficient manufacturing process for small batches of prototypes that carry intricate designs with complex geometries – which would otherwise require equally complex (and costly) tooling in the case of injection molding. Additive manufacturing is also optimized for tackling numerous design iterations, making it a boon for ongoing product development and refinement.

On the other hand, injection molding is the better service for prototypes that must be virtually identical to the final production parts. Your upfront costs will likely be greater, and the setup/tooling process requires longer lead times, but the end prototypes that you receive will be manufactured without compromise. This is sometimes a requirement for extremely demanding industries, such as precision aerospace applications or specialized injection molded automotive parts.

3D Printed Prototypes:

- Rapidly produce custom prototypes without developing costly, complex tooling first.

- Capable of producing virtually any complex part design into a functional prototype to test, refine, and implement additional design changes.

Injection Molded Prototypes:

- Production-ready prototypes that exhibit superior strength and surface finish.

- Streamline your project from the prototyping process into full-scale production.

- Mold tooling can be fabricated from aluminum or softer steels like P20 to minimize costs and turnaround time compared to production injection molding.

Small Batch and Low-Volume Manufacturing

For low-volume manufacturing projects requiring less than 100 products, 3D printing services often provide the quickest and most cost-effective solution. Our DLS printing capabilities can achieve production-ready parts with a high level of infill density, satisfying many modern product requirements for strength and performance. Even for some mid-volume projects totaling <10,000 products, additive manufacturing is often the choice due to the process’ design freedom and rapid turnaround.

However, many small-volume projects are better served through the injection molding process. When higher strength, consistency, and/or extreme design complexity need to be accommodated, injection molding generally offers a more reliable solution than 3D printing services.

Moreover, low-volume injection molds can often be fabricated faster and cheaper than high-volume production molds. This is due to the fact that the service life of the tooling will be limited, enabling the use of easier-to-machine aluminum or softer tool steels. A low-volume injection molding specialist can therefore help bridge the gap in turnaround time and design freedom via rapid injection molding (RIM).

3D Printing for Low-Volume Production Parts

- Minimum lead times and unbeatable turnaround speed for low-volume products.

- The utmost in design freedom, allowing for product modifications and refinements at virtually any point in the production cycle.

Low-Volume Injection Molding Services

- Ideal for production-ready low-volume products that demand the utmost in quality, consistency, strength, and performance.

High-Volume Manufacturing and Full-Scale Production

While additive manufacturing has been most commonly used for rapid prototyping and small-batch manufacturing projects, advances in technology have made it possible to mass produce certain products using 3D printing. However, in the current manufacturing space, injection molding services are almost always the most efficient option for tackling high-volume production runs.

3D printed production parts are stronger and higher quality than ever, but still generally can’t match the ultimate quality and efficiency of injection molding. Plastic injection molding services thus remain the most efficient method for manufacturing high volumes of production-ready products.

Quality American Injection Molding Services and Additive Manufacturing Solutions

Since 1982, Elite Mold & Engineering has remained one of the Michigan region’s leading injection molding companies. Embracing the latest production technologies, our manufacturing capabilities today include 3D printing services which compliment our leading expertise in prototyping and low-volume projects.

Based out of Shelby Township, our company is uniquely set up to deliver the rapid response and quick turnaround that will give your products an edge in their respective markets. Dedicated to delivering superior quality, our company is an ISO 9001:2015 certified and ITAR registered manufacturer.

Communication

Confidentiality & ITAR

No Additional International Shipping or Tariff Cost

Qualification All In One Place

Let Elite Become Your Preffered Domestic Tooling Partner

Discover the multitude of benefits when you choose a domestic tooling source. With our expertise, experience, and commitment to quality, we provide a multitude of key advantages that will streamline your operations. Our local presence ensures seamless communication, offering you the convenience of direct and efficient collaboration. Elite’s stringent quality control measures guarantee precision and reliability, delivering top-notch tooling solutions tailored to your specific needs. Also, by choosing a domestic source, you support local businesses and contribute to the growth of your community. Our quick turnaround times ensure that you stay ahead of the competition, enabling you to meet even the tightest project deadlines. Embrace the numerous advantages of a domestic tooling source and watch your productivity soar.