CommunicationShipping & Tariff CostConfidentiality & ITARQualification All in One Place

Four Advantages Of Utilizing A Domestic Tooling Source:

Elite Mold & Engineering – Domestic Tooling Experts

Recent Posts

Addressing the Common Design Issues in Injection Molding Plastics

At Elite Mold & Engineering, we try to ensure the success of every injection molding project by addressing any design issues well before production is underway. Our integrated prototyping and product development services bring any potential issues to light, while...

Rapid Injection Molding: An Increasingly Crucial Service for Supply Chain Sustainability

Rapid injection molding is one of the key ways that American manufacturers have risen to the challenges of today’s global supply chain. It’s no secret that most plastic products are made in China. Traditionally, when customers thought of molded plastics, Chinese...

A Guide to STL Files for 3D Printing Projects: STL vs. CAD Models and Other Critical Info

Creating a custom STL file for your parts is one of the crucial early steps in the 3D printing process. Essentially, an STL file is a 3D model that precisely describes the surface geometry of your part as a complex structure built up from interlinked triangles. We’ll...

Rapid Prototyping Techniques Compared: Injection Molding, 3D Printing, and CNC Machined Prototypes

Elite Mold & Engineering specializes in three of the most flexible high-speed prototyping services on the market: rapid injection molding (RIM), 3D printing, and low-volume CNC machining solutions. Each of the three processes comes with its own set of unique...

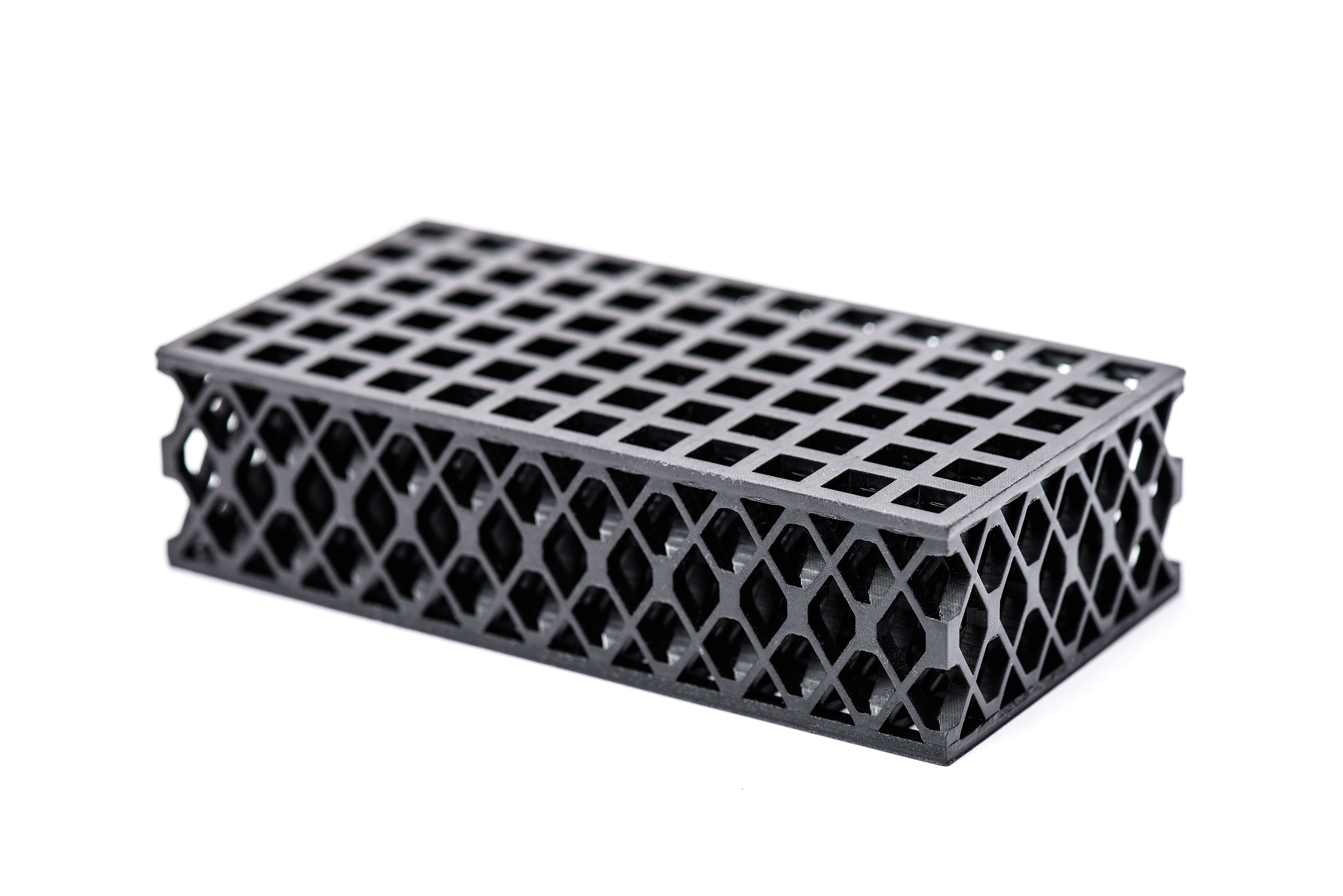

Prototyping is a highly intricate process that can be streamlined through the art of additive manufacturing. Today’s 3D printing technology allows us to build your prototypes much faster, more accurately, and make iterative design changes far more easily.

While many of today’s 3D printing services offer rapid results with minimal involvement, there are some crucial questions you should ask before sending your custom part designs off to be printed.

3 Questions to Consider Before You Begin Your Prototyping Project:

Do you require prototype design assistance?

If your prototype design is fully developed and complete, that’s one thing – you simply need a quality-backed 3D printing service provider to bring your designs to life. However, in many cases, the prototyping phase is your best opportunity to further refine and optimize your products for cost and/or performance.

Elite offers assistance at every stage of your prototyping project – from initial product design to iterative improvements to low-volume production. Through value-adding solutions such as design for manufacturability (DFM) and material optimization, we can help you achieve the highest quality, most cost-effective prototype possible.

Will you be transitioning your project to high-volume injection molding?

Another important consideration is your future production goals. Are your prototypes simply proofs of concept, a low-volume run, or do you intend to transition into full-scale injection molding?

If it’s the latter, you should consider a full-service, single-source provider that can tackle both phases of your project. At Elite, the collaborative design and prototyping process gives us the perfect segue into high-volume injection molding when required, streamlining your products to market.

What’s the best material choice for printing your custom prototypes?

Prototypes come in many different shapes and sizes, with many different budgetary and performance constraints, and many different end-use applications, etc. All of these considerations will factor into the material choice for your project.

Even if you have a material in mind, you may even want to choose an additive manufacturer that offers multiple material options along with the expertise to back them up. In many cases, the custom prototyping process is refined through trying out different materials and achieving unique results for the application at hand.

At Elite, we utilize Carbon Digital Light Synthesis (DLS) 3D printing technology along with a wide range of materials. Our options include:

UMA 90 (Urethane Methacrylate)

A rigid single-part resin similar to conventional SLA resins.

CE 221 (Cyanate Ester)

A high-performance thermoplastic with outstanding strength, rigidity, and heat resistance.

FPU 50 (Flexible Polyurethane)

A rigid two-part resin with high impact strength and resistance to repetitive stresses.

SIL 30 (Silicone Urethane)

A soft, biocompatible, and tear-resistant elastomer that is ideal for skin-contact products.

RPU 70 (Rigid Polyurethane)

A rigid two-part resin with outstanding strength and stiffness, outperforming similar plastics such as ABS.

RPU 130 (Rigid Polyurethane)

A two-part resin that provides outstanding durability and high heat resistance.

EPU 41 (Elastomeric Polyurethane)

A production-grade elastomer with exceptional energy return, high resilience and low temperature retention of elastomeric properties.

EPU 40 (Elastomeric Polyurethane)

A high-performance elastomer that offers energy absorption, high elasticity, and outstanding tear resistance.

LOCTITE® IND147™ Resin

A premium one-part resin that provides high stiffness and high thermal resistance.

LOCTITE® IND405™ Clear Resin

A one-part clear resin that produces tough prototypes with a frosted clear aesthetic.

EPX 86 FR

A high-strength resin that is flame-retardant while offering exceptional toughness and long-term stability.

EPX 82 (Epoxy)

An epoxy resin that offers great durability, stiffness, and temperature resistance, ideal for a range of automotive and consumer applications.

Michigan’s Leading 3D Printing Prototype Specialist

Elite Mold and Engineering is proud to be one of the nation’s leading injection molding companies offering 3D printed prototyping solutions. Our additive manufacturing capabilities are engineered to compliment our plastic injection molding processes, offering our customers a streamlined, single-source solution from prototype to production.

Communication

Confidentiality & ITAR

No Additional International Shipping or Tariff Cost

Qualification All In One Place

Let Elite Become Your Preffered Domestic Tooling Partner

Discover the multitude of benefits when you choose a domestic tooling source. With our expertise, experience, and commitment to quality, we provide a multitude of key advantages that will streamline your operations. Our local presence ensures seamless communication, offering you the convenience of direct and efficient collaboration. Elite’s stringent quality control measures guarantee precision and reliability, delivering top-notch tooling solutions tailored to your specific needs. Also, by choosing a domestic source, you support local businesses and contribute to the growth of your community. Our quick turnaround times ensure that you stay ahead of the competition, enabling you to meet even the tightest project deadlines. Embrace the numerous advantages of a domestic tooling source and watch your productivity soar.